Top Exporting Countries of Oxidized Bitumen in 2025

Global Snapshot of Top Exporting Countries of Oxidized Bitumen

The market for Oxidized Bitumen (also known as blown bitumen) is gaining global traction thanks to its superior thermal stability, adhesion and durability — characteristics that make it ideal in roofing, waterproofing, industrial coatings and adhesives.

According to market research, the Asia-Pacific region leads the segment, with rapid infrastructure growth driving demand. In this context, identifying and understanding the key exporting countries in 2025 offers strategic insight for buyers and suppliers alike.

Leading Exporters in 2025

- Iran — Based on recent market briefs, Iran ranks among bitumen exporters, including oxidized grades, with export volumes in the range of 8-10 million MT annually. Its competitive pricing, refining capacity and strategic proximity to high-demand markets (East Africa, South Asia, Middle East) give it a strong edge.

- United Arab Emirates (UAE) — With annual volumes around 4-5 million MT, the UAE leverages its logistics hub (Jebel Ali) and acts as both exporter and re-exporter of high-performance bitumen grades.

- India — Although more known as a large consumer, India has emerged as a significant exporter of specialty bitumen/oxidized bitumen (3-4 million MT) to neighboured markets like Nepal, Bangladesh and Sri Lanka.

- Singapore — A smaller volume exporter (2-3 million MT), it focuses on premium and specialty grades of oxidized bitumen, serving Southeast Asia and Australia.

- South Korea — With strong refining capability and technical know-how, South Korea exports about 2-2.5 million MT of bitumen including oxidized grades, particularly to East Asian markets.

These countries dominate due to a combination of refining capacity, geographic logistics, and strong domestic demand for related construction and industrial sectors.

Why These Countries Excel in Oxidized Bitumen Exporting

Several key factors underlie their leading positions:

-

Refinery & processing capacity: These nations possess advanced refining infrastructure and the ability to produce blown/oxidized bitumen.

-

Strategic logistics & port access: Proximity to major construction markets and cost-effective shipping routes matter.

-

Strong demand in construction & infrastructure: Rapid growth in roads, roofing, waterproofing fuels demand.

-

Competitive pricing & grade variety: Offering multiple grades (e.g., 115/15, 90/40) tailored to client needs enhances export potential.

Outlook & Opportunities for 2025

Looking ahead into 2025, demand for oxidized bitumen is expected to continue growing — thanks to global infrastructure investments, rising waterproofing applications and industrial usage. For exporters and suppliers, this means:

-

Targeting emerging markets (Africa, Latin America) where infrastructure booms are underway.

-

Offering diverse packaging and logistics solutions to ease export hurdles.

-

Leveraging quality certifications and specialty grades to differentiate in competitive markets.

-

Monitoring crude-oil price volatility and regulatory shifts which could affect production costs and margins.

Global Market Dynamics and Quality Standards

The global trade of oxidized bitumen is increasingly shaped by environmental regulations and quality certifications. Buyers in Europe, Africa, and Asia now demand materials that comply with ISO and CE standards, ensuring safe application in construction and industrial sectors. Exporters like Faragam Bitumen have adapted by implementing strict quality control systems, using modern oxidation processes that reduce emissions and ensure a consistent product. This adherence to international standards not only enhances trust but also opens new markets where regulatory compliance is crucial for import approval.

Sustainability and Future Developments

As sustainability becomes a global priority, the bitumen industry is moving toward eco-friendly production and packaging solutions. Many exporters, including Faragam Bitumen, are investing in cleaner technologies to minimize carbon footprint during production and transport. Moreover, innovative packaging such as recyclable blocks and moisture-proof wrapping is becoming standard for high-end clients. These advancements, combined with steady infrastructure growth worldwide, position oxidized bitumen as a strategic industrial material for the next decade with Iranian suppliers playing a vital role in the international supply chain.

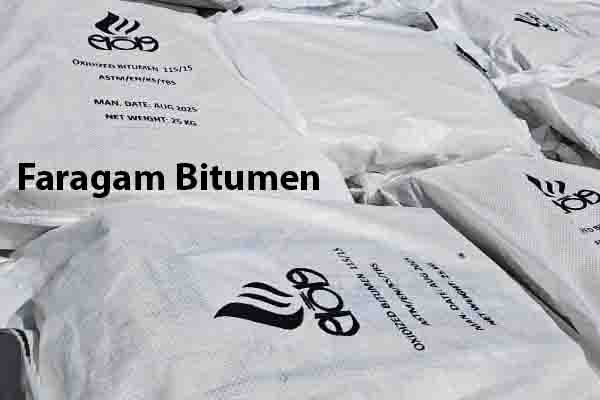

Faragam Bitumen

A Reliable Iranian Exporter

Among Iran’s leading suppliers, Faragam Bitumen stands out for its commitment to quality, reliability, and customer-centric export service.

The company produces a full range of oxidized bitumen grades (e.g., 115/15, 90/40, 95/25) with stable softening points and penetration consistency, suitable for industrial and construction applications.